Written & Photographed by Kalie Ilana Cassel-Feiss

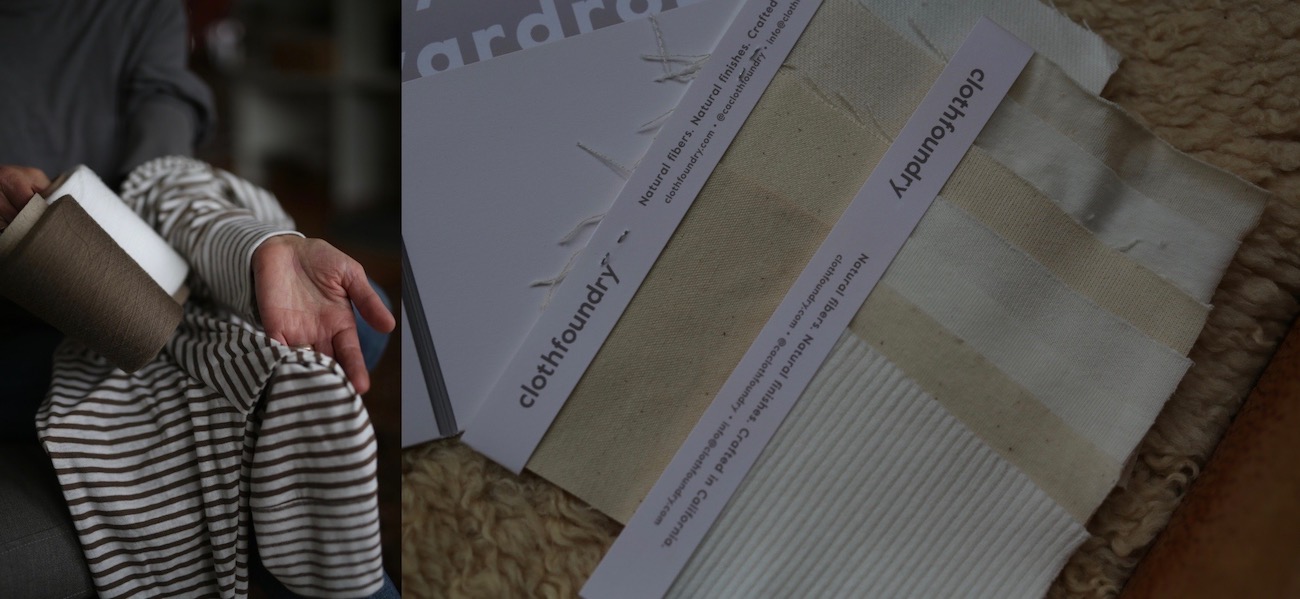

From the land where the cotton is grown, to the spinning mills where it becomes yarn, to the manufacturing facilities that form fabric and fashion; from the hands of the farmers to the mill workers, from dyers to designers, and makers to wearers, Lydia Wendt works from this eagle-eyed vantage point, carefully coordinating and collaborating with each person and place involved. Gracefully bringing together all the elements of locally grown, milled, and made organic fabric, her work takes shape with California Cloth Foundry: textiles and apparel in collaboration with nature.

Lydia, a New Yorker by birth and an apparel designer for the last 25 years, first began her career attending the Fashion Institute of Technology and working in the “Rag Trade” on 7th Avenue in the Garment District. She started out designing apparel in large teams at companies such as Perry Ellis America with Tom Ford, Calvin Klein, Jones NY, and Made in America (Harris/Wallace Inc; a private label manufacturer producing mainly with factories located in New York’s tri-state area). She felt a spark when she started to work more intimately with regional, as well as European mills, learning about the textile industry from a closer perspective. “I talk about reverse engineering all the time,” Lydia explains, “meaning you have an end goal/product in mind, and you reverse all the way back to the base materials, fibers and components to chose and customize the most appropriate for the end goals — instead of the more typical industry standard where we find fabric and try to make something, anything from it.” This approach became a guiding methodology as Lydia joined forces with Fibershed to reverse engineer the Backyard Hoodie, researching and creating an appropriate fabric from the ground up.

Lydia’s passion for apparel design continued to move all the way down the supply chain, as she was fascinated with the entire process from start to finish. She began to learn about conventional systems of printing and dyeing. Teaching textile design at the Academy of Art in San Francisco, Lydia taught conventional printing, dyeing, sublimation, and surface design — utilizing only synthetic dyes and on occasion a real indigo or traditional batik (as the exception to the rule) in her classroom.

In 2013, she connected with Fibershed when she took one of Rebecca Burgess’s mushroom dyeing workshops with wool and silk; and was invited to help with the Backyard Hoodie project. Up until that point, her teaching and design largely tapped into her extensive knowledge of the conventional world of textiles. As she found herself captivated by natural dyes, and with the plants and the mushrooms themselves, she began to fully explore what was possible.

“I was never given the opportunity to work in natural pigments, dyes or green chemistry, with the exception of natural indigo when I was a designer,” she laments. “And that was for Perry Ellis America’s denim; never produced due to exorbitant costs.” Deepening her awareness of the gaps between natural materials/processes and conventional industry practices, Lydia knew that more reverse engineering was needed.

“I love the craft — the idea, and process of the making; the origin, the materials. I love digging deeply into what those materials are, getting the clay underneath your nails, and oh! the indigo!” Lydia’s love of apparel became focused on the fabric style: the drape, the weave, the knit, and how it performs. She learned quickly that there are so many more variables with natural materials than conventional ones, which proved to be a worthy challenge to bringing natural materials into the modern industry of volume textiles and apparel manufacturing. Lydia saw how petroleum-based dyes have always been extremely stable. “With natural dyes it is harder to control the results, and therefore can be risky for business,” she explains.

“I tell the conventional world of manufacturing that the quality assurance (color, shrinkage, weight, performance of the fabric), lot by lot, color by color, room by room will be slightly different each time and that can be okay. The fabric is alive, and it reacts, moves, shrinks, stretches, twists, torque, and breathes differently, in every different element of its character including color.” Lydia has found that the conventional industry can accept white as well as naturally color-grown cottons, since they can be stabilized, to a degree, and their idiosyncrasies have already been globally accepted as the norm within the street/casual denim and t-shirt world. And clothing that is finished or dyed with natural sources provides an assurance for the wearer: “When you wash the cloth, it might shrink a bit, but at least it won’t bleed on you like some conventional dyes do. Even if it does bleed, or rub off, on you, it’s just a root or an acid from a fruit,” she remarks, referencing the origins of different plant-based dyestuffs and fabric finishes.

For California Cloth Foundry, Lydia works with an expansive supply chain. She’s in personal contact with the cotton farmers and hopes to soon link up with wool producers as well as Bastcore, the Nebraska-based hemp fiber processor that has contributed to Fibershed’s hemp blending research. To get the fiber to be spun, Lydia works with the owners of the spinning mills and on-site technicians to make the yarn. Once the yarn is made, she continues to work with the owners and management teams of knitting and wovens mills: often directly with the president of the dye house, the owner of the cutting room, the line managers of the sewers, and all the people who coordinate packaging and labeling.

The complexities of each phase and the coordination with each manufacturing collaborator is a lot to manage, but her inspiration is simple: her children. “Because it’s the future of their earth, their ethics, and their happiness,” she says. “They’re living in a fast world, but they’re happy to see what I’m doing, to slow down for a moment and inquire about a new cloth or color and they get ‘into it’, as I’ve overheard them and their excitement when they discuss what we do with their friends. They can see our results and progresses, and they keep me going.” Lydia’s daughters are both in high school, and frequently pipe in with their opinions on the latest clothing design and fashion world today. “This is really is about ecology,” says Lydia. “And we are trying to make it really beautiful. It’s an intersection of both the aesthetic and the environment.”

The concept of California Cloth Foundry would have been impossible for Lydia had her supply chain been only on the East coast or somewhere abroad. “The only way I could do this, given budget and logistical limitations like raising my daughters, was to work here and directly with the innovators, roll-up my sleeves and say ‘I’ll be here every moment with you.’ And it also makes for really nice community.” The work is hard, she says, but the spirit and the triumph are all in the collaboration. “These people are hardworking and creative, including the farmers. People may not realize how creative and innovative farmers are. Here in America, the (fiber producing) resources are scarce, the margins are low, the need to compete is high… working with them always inspires.”

The care and dedication to ethical, ecological production becomes tangible: “You can feel it through the cloth,” she says. “Because everyone that contributes to our product development is excited to give their input, it becomes something better, something you didn’t realize you could do alone. Because my team and I work very closely with our supply chains of innovators, rather than remotely digitally overseas, we all feel that we make a better product.”

California Cloth Foundry sells their fabrics currently online, and plans to launch their new apparel collection in early summer, with offerings of beautiful knitwear in the form of long sleeve and short sleeve shirts, pants, shorts, tank tops, hoodies, cardigans, underwear, and a camisole; in gorgeous natural colors of Coral, Charcoal, Heather, Natural, and Stripe. Look for their upcoming launch in June.

Learn more about California Cloth Foundry by visiting them on their website here and by connecting on Facebook and Instagram @caclothfoundry